Forklift Frenzy: A Comprehensive Guide to Forklifts

Introduction

Welcome to Forklift Frenzy, the ultimate guide to forklifts brought to you by Upscale Bargain. In this comprehensive resource, we will provide you with all the information you need to make an informed decision when buying a forklift for your business.

Why Choose Upscale Bargain?

At Upscale Bargain, we understand that investing in a forklift is a significant decision for any business. That's why we strive to offer the highest quality forklifts at competitive prices. With our extensive range of forklift models and our commitment to excellent customer service, we are confident that we can exceed your expectations.

Types of Forklifts

There are several types of forklifts available, each designed for specific applications. Understanding the different types will help you choose the right forklift for your business needs.

1. Electric Counterbalance Forklifts

Electric counterbalance forklifts are the most common type of forklifts used in warehouses and indoor spaces. They are powered by electric batteries, making them environmentally friendly and suitable for indoor use.

2. Reach Trucks

Reach trucks are designed for narrow aisle operations, allowing them to maneuver easily in confined spaces. These forklifts come with extending forks that can reach higher storage racks, maximizing vertical storage space.

3. Pallet Jacks

Pallet jacks, also known as walkie pallet trucks, are manual or electric-powered forklifts used primarily for horizontal transportation of palletized loads. They are widely used in warehouse environments where quick loading and unloading is required.

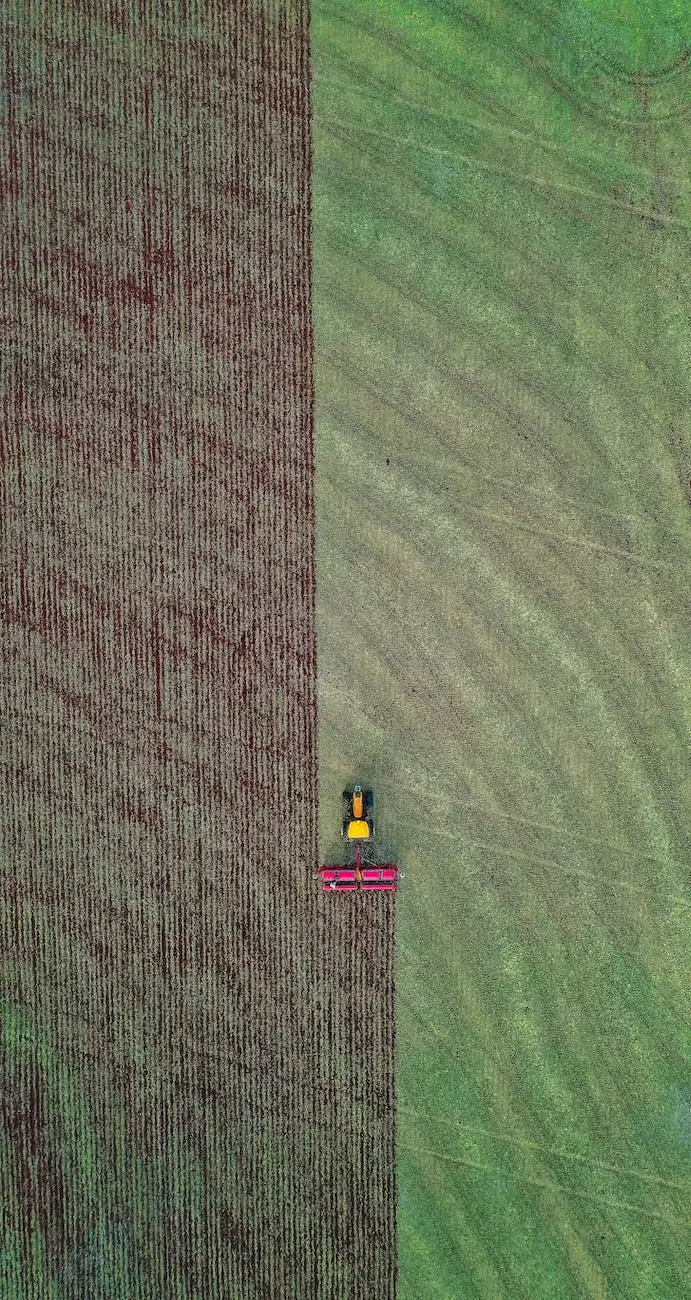

4. Rough Terrain Forklifts

Rough terrain forklifts are designed for outdoor applications and uneven terrain. With their rugged tires and larger size, these forklifts can handle challenging environments such as construction sites or agricultural settings.

5. Order Pickers

Order pickers are ideal for order fulfillment operations where high-level picking is required. They allow operators to retrieve items directly from the racks, improving efficiency and reducing picking time.

Key Features to Consider

When choosing a forklift, it's essential to consider various features to ensure it meets your business requirements. Here are some key features you should evaluate:

1. Lift Capacity

The lift capacity determines the maximum weight the forklift can handle. It's crucial to assess your typical load requirements and select a forklift with an appropriate lift capacity to handle your workload.

2. Mast Type

The mast is the vertical assembly on the front of the forklift that lifts and lowers the load. Different mast types, such as standard, duplex, and triplex masts, offer varying lifting heights and visibility. Consider your warehouse layout and stacking requirements to choose the right mast type.

3. Power Source

Different forklifts come with various power sources, including electric, propane, and diesel. Each power source has its advantages and considerations, such as indoor or outdoor use, operating costs, and emission levels. Evaluate your operational needs and environmental factors before selecting a power source.

4. Fork Length

Fork length determines the size of the loads the forklift can manage. Longer forks are suited for larger loads, while shorter forks are ideal for smaller, compact loads. Consider your typical load sizes and space constraints to choose the appropriate fork length.

Proper Forklift Maintenance

Maintaining your forklift is crucial for ensuring its longevity and safe operation. Here are some essential maintenance tips to keep in mind:

1. Regular Inspections

Perform routine inspections to identify any potential issues before they become serious problems. Check the tires, brakes, forks, and other components to ensure they are in good working condition.

2. Scheduled Servicing

Follow the manufacturer's recommended service schedule to ensure that your forklift receives timely maintenance. Regular servicing includes oil and filter changes, hydraulic system checks, and overall equipment inspections.

3. Operator Training

Properly train your forklift operators to handle the equipment safely and efficiently. Ensure they understand the correct operating procedures and safety protocols to minimize the risk of accidents and damage to the forklift.

4. Battery Maintenance (for Electric Forklifts)

If you have electric forklifts, proper battery maintenance is essential. Follow the manufacturer's guidelines for charging, watering, and cleaning the batteries to maximize their lifespan and performance.

Contact Upscale Bargain Today!

Now that you are equipped with valuable insights into forklifts, it's time to choose the right forklift for your business needs. Contact Upscale Bargain today and let our expert team guide you through the process. We are committed to helping you find the perfect forklift that meets your requirements and exceeds your expectations.